& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

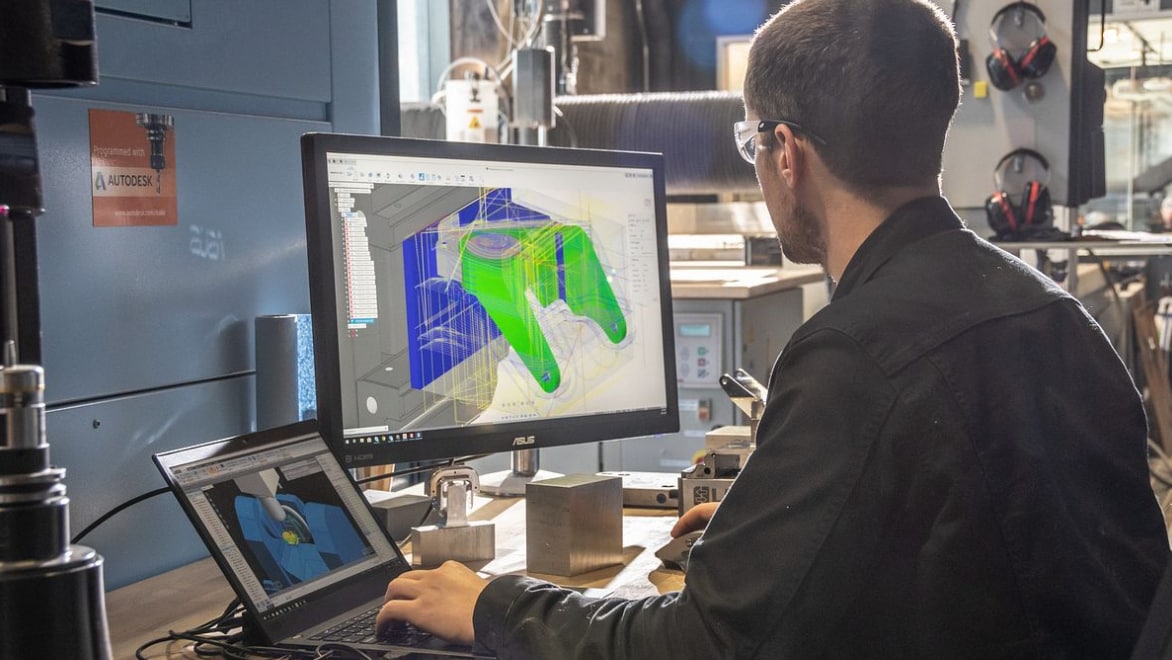

“CNC” stands for computer numerical control. CNC machines come in a various shapes and sizes and frequently perform the first stage of fabricating a component or part by removing material. After developing a part in CAD (computer-aided design) software, CAM (computer-aided manufacturing) software is used to generate toolpaths – instructions for a CNC machine on how to generate toolpaths that will control the motion and behaviour of the machine, cutting tool and workpiece during the manufacturing process.

CAM software, such as Autodesk Fusion, creates a digital file (NC program) containing all the necessary instructions to control how the CNC machine will function. A configurable post processor is used to control the precise contents of the NC program, including different G- and M-codes to suit the NC controller type (such as Heidenhain, Siemens or Fanuc) as well as different configurations of linear and rotary axes (for example 3-axis, 4-axis or 5-axis with rotary axes on the head and/or table).

Before choosing a CNC software, first assess the types of CNC machines, operations and materials you want to use and the complexity of the parts you will create. Different CNC software will have varying compatibility for specific CNC machines – and varying utility for CNC operations, such as milling, turning, plasma cutting or 3-axis vs. 5-axis toolpaths. Make sure any CNC software options will work well with your entire workflow, including compatibility with CNC machines and their controllers, the necessary file formats and any software extensions or plug-ins.

Next, consider how comprehensive and robust you want the CNC software to be. For example, some CNC software integrates CAD, CAM and CAE (computer-aided engineering) and full simulation features into one package. In comparison, other program may be as simple as sending G-code to a CNC machine. Also, differing software capabilities and levels of customer support come at varying prices. CNC software may range in cost from free to thousands of dollars and may require ongoing costs for support, upgrades and/or subscriptions. Consider your budget compared to each CNC software program’s features, quality and tech support. If in doubt, try a free trial or demo before you buy.

CNC software/platforms such as Autodesk Fusion integrate CAD and CAM to keep design and manufacturing processes as connected as possible; when creating a design, engineers must keep the manufacturing process in mind from the beginning. Once loaded with stock material, the CNC machine performs the programmed operations, including cutting or using other tools during the machining process. Finally, the toolpaths are turned into G-code, which controls the machine movements and generates the finished product. The manufacturing workspace in Autodesk Fusion is responsible for interpreting toolpaths and exporting them as G-code for a CNC machine.

Learn about some of the top benefits of CNC software from Autodesk

Combining CNC software with CNC machines makes the same precision and accuracy of 3D CAD models physically possible. Some CNC software, such as Autodesk Fusion, also includes simulation abilities that test the machining process virtually to identify potential errors and waste ahead of time.

CNC software from Autodesk integrates CAD and CAE capabilities with its CAM functions, making manufacturing smoother overall. CNC machines can also run efficiently all day, every day, with the flexibility to make quick changes straight from the CNC software.

CNC machining automates much of its fabrication behind the machines’ enclosures, so human operators and programmers are less directly involved in machining operations. While this step does not eliminate the potential for accidents, it greatly reduces the risk of injury.

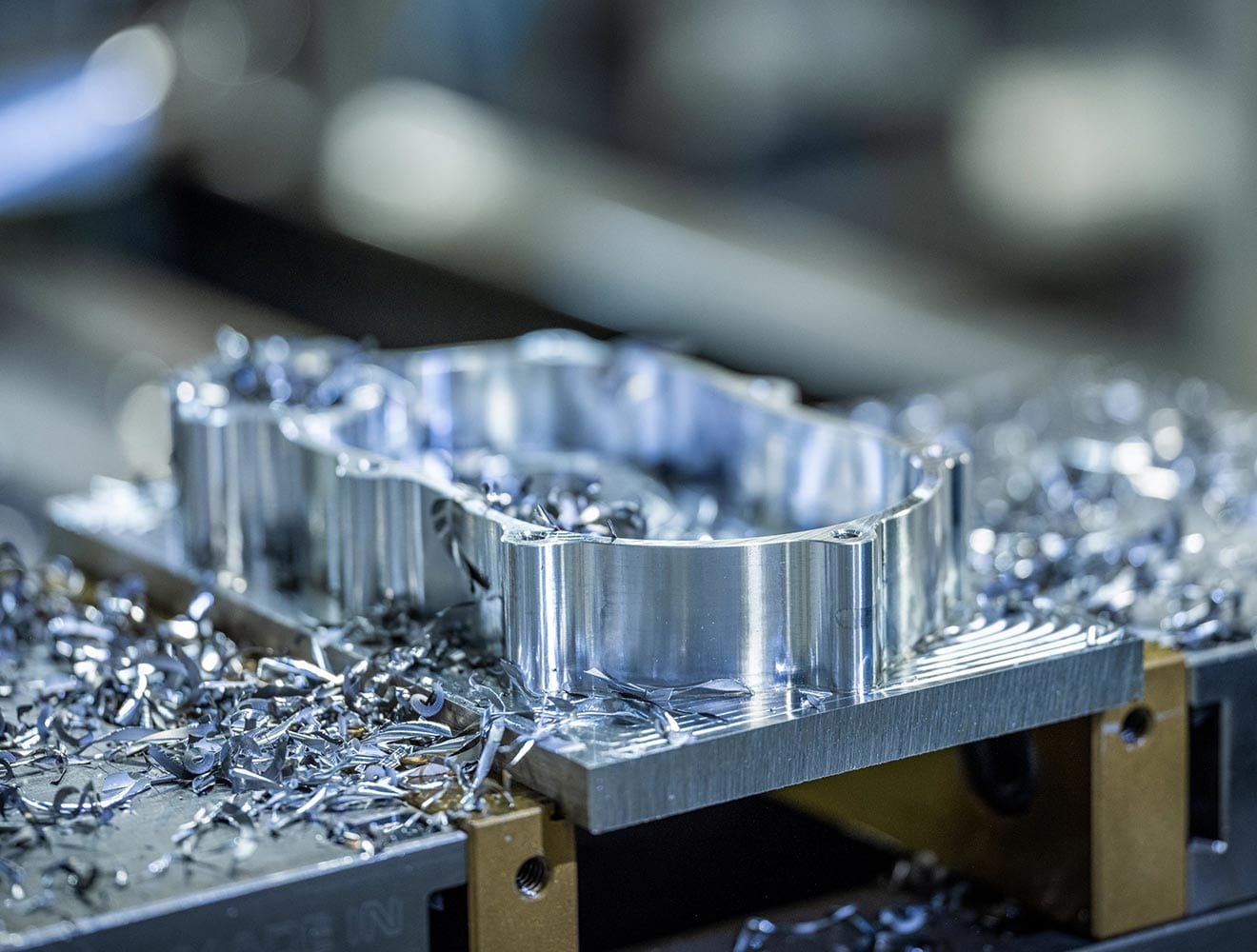

The first step in many CNC machining operations, roughing, removes as much material as possible from the stock before zeroing in on details. The Adaptive Clearing capability in Autodesk CNC software produces collision-free roughing and reduces the need for long repositioning moves so manufacturers can deliver high-quality parts in less time.

With 2-axis milling, the cutting tool moves across two axes, X and Y, while 3-axis milling adds the Z axis, where the tool head moves up and down. Upgrading your CNC software to offer 3-axis toolpaths can accomplish the same milling jobs with fewer setups – leading to less machine time and corresponding cost savings. With 4-axis milling, one rotational axis is added.

Image courtesy of PrintCity MMU

With 3+2-axis machining, also called positional 5-axis machining, the cutting tool moves across three linear axes (X, Y and Z) and can tilt to different angles along two rotational axes (A or B, plus C). By contrast, simultaneous 5-axis machining, also called true 5-axis machining, moves both the cutting tool and the workpiece along X, Y, Z as well as A/B and C axes simultaneously. 3+2-axis machining has the advantages of reducing setups, avoiding collisions and using shorter, more rigid tools without the level of complex CNC software and hardware programming that simultaneous 5-axis machining requires. However, simultaneous 5-axis machining can achieve more complex organic shapes and contours, as well as reduce machining time and waste.

CNC turning typically involves lathe machines that spin the stock along a stationary cutting tool. Turning operations include removing material from the front of the stock or from the outside of the part; adding threads to the part; and boring, or creating holes, in the part. Turning does certain jobs more efficiently than milling, but “mill-turning” operations can combine both turning and milling when your CNC software and machinery can support it.

Image courtesy of Precinov

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication and metals-based additive manufacturing.

Discover how Autodesk customers use CNC software in their projects.

CONTURO PROTOTYPING

To make the CNC machining of complex parts faster, less expensive and more practical, Conturo Prototyping uses the "Autodesk Fusion Manufacturing Extension" to simplify part design, collaborate more effectively, automate setup and ultimately programme multiple parts per day for 5-axis machining.

Image courtesy of Conturo Prototyping

EVOLVE

Generative design is not only for additive manufacturing. Find out how engineering company Evolve used Autodesk Fusion’s generative design capabilities and 2.5-axis CNC machining to reduce the weight of an electric hypercar component by 40%.

Image courtesy of Evolve

CAVALIER TOOL & MANUFACTURING

As “metal-removal experts”, Cavalier relies on the powerful and user-friendly Autodesk PowerMill CNC software to optimise the company’s spindle utilisation, allowing it to use smaller cutters with consistent cutter paths and significantly reducing machine time.

Image courtesy of Cavalier Tool and Manufacturing

PRECISION MOULD & MACHINING

Hear how Precision Mould & Machining improved productivity, quality and the bottom line since switching its legacy CAD/CAM software to Autodesk PowerShape and PowerMill for its 3-axis and 5-axis CNC machining.

Image courtesy of Precision Mould & Machining

Learn more about CNC machining software with these helpful resources from Autodesk.

CNC software like Autodesk Fusion translates its CAD 3D models into G-code and toolpaths that instruct CNC machines how to create the part physically. Find out more about the types and benefits of CNC programming.

This skill-building course for digital manufacturing takes you through the entire part-creation process, from blueprint reading to CAD modelling, CNC machine setup, programming CAM toolpaths with Autodesk Fusion CNC software and digital verification.

Explore the work coordinate system (WCS) principles used to control CNC machining and how work and tool offsets account for different tool lengths.

Learn how to save recurring CNC machining toolpaths for recall in just a few short video tutorials.

This YouTube playlist dives deep into essential machining techniques, tools and strategies that drive modern machining processes.

Ready to step up? Dive into this expert-level CNC machining course for recognising multi-axis geometry and controlling the toolpaths for 3-axis, 4-axis and 5-axis machines.

Learn more about CNC machining software from these top questions users frequently ask.

The main types of CNC software include computer-aided design (CAD) software, which creates 2D and 3D models of parts and assemblies and computer-aided manufacturing (CAM) software, which translates CAD models into G-code or another code that informs CNC machines how to produce the part. CNC simulator software simulates the CNC machining of parts to identify potential errors before physically attempting fabrication. Some CNC software, such as Autodesk Fusion, includes CAD, CAM, simulation and more in a single package.

Also, CNC software is available as offline and online programming. Offline programming permits the creation of NC code as the machine is in operation, increasing productivity and shop-floor throughput. In contrast, online programming does not allow the machine to produce parts while the operator writes CNC software code.

To ensure the CNC software of your choice is compatible with your machinery, you can check the machine manufacturer’s manual and/or website for recommendations on the software, operating systems, communication protocol and hardware interfaces that can be used with the machines. Check the software company’s technical support to ensure the software supports G-code or other file types that work with your machines.

If it’s still unclear, check with online user groups, forums or reviews for first-hand feedback on your CNC machine and software pairing. If available, try a free trial or demo of the software before buying to test it with your CNC machinery.

One of the most significant costs associated with CNC machining is the CNC machine itself. Entry-level machines start at around $5,000 USD, with high-end machines reaching upward of $500,000 USD. The cost depends on factors like size, power, spindle speed, multi-axis capabilities, accuracy, the capacity of tool changers, multi-pallet for increased automation, high-pressure through spindle coolant and more. Once you have a machine, you must purchase cutting tools to machine parts. To generate the instructions required for CNC machining, it’s also common to subscribe to computer-aided manufacturing (CAM) software. So, while there’s no one-size-fits-all answer, CNC machining requires some upfront investment.

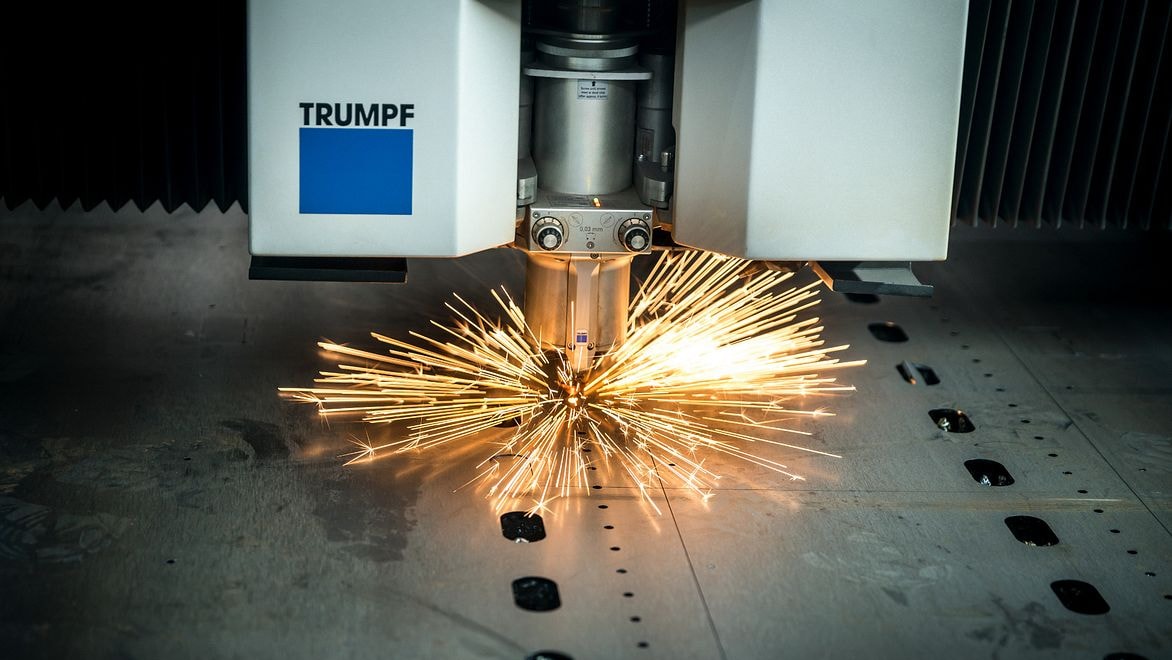

Milling is one style of CNC machining. CNC machining is any process where a machine controlled by a computer manufactures a part. In milling, a cutting tool spins at high speeds and advances into or across the workpiece to remove material. Other types of CNC machining include turning, routing, plasma cutting and water jetting. Turning and milling can be combined into a single machine, as can additive and subtractive operations, creating even more complex , such as hybrid manufacturing, which combines subtractive and additive manufacturing.

3D printing or additive manufacturing, is the process of depositing layers of material to build up the desired geometry. Generally speaking, CNC machining refers to subtractive processes where the material is removed from the workpiece, resulting in the desired geometry. While 3D printing processes can create more complex geometry like internal latticing, parts need support during printing to prevent failure. CNC machining generally produces more accurate parts and can be significantly faster, especially when manufacturing single parts.

Many manufacturers are using additive and subtractive manufacturing together. In simple cases, they 3D print a part, then use CNC milling to machine critical features such as holes, slots and mating faces that need additional precision. In more niche applications, hybrid manufacturing can inter-weave additive and subtractive processes to combine the best of both technologies. For example, a manufacturer may print a hollow part and include CNC machining steps at regular intervals throughout the 3D print process instead of doing all the printing followed by all the CNC machining.

CNC stands for Computer Numerical Control, which means that a computer controls what the machine does, including (but not limited to) the spindle speed, feed rate and position. To program the computer — often called a control — a person can use computer-aided manufacturing (CAM) software. CAM software for CNC generates a series of instructions called toolpaths and then generally uses a post-processor to translate that toolpath data into code the machine can read. A person would then transfer that code onto the machine and run it to produce the final part.

Yes — Autodesk Fusion includes a powerful and easy-to-use CNC software solution that can control various CNC machines, including mills, lathes, routers, mill/turn machines, plasma cutters, water jets and lasers. Autodesk Fusion also integrates CAD, CAE, ECAD and CAM into a single solution to reduce data loss and improve process reliability for CNC machining and other downstream processes.

.jpg)