& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Shoe design and manufacturing encompass the creation and production of footwear.

The design stage involves developing a shoe concept, which includes aesthetics, comfort and functionality. This often involves 3D modelling and prototyping using software like Autodesk Fusion.

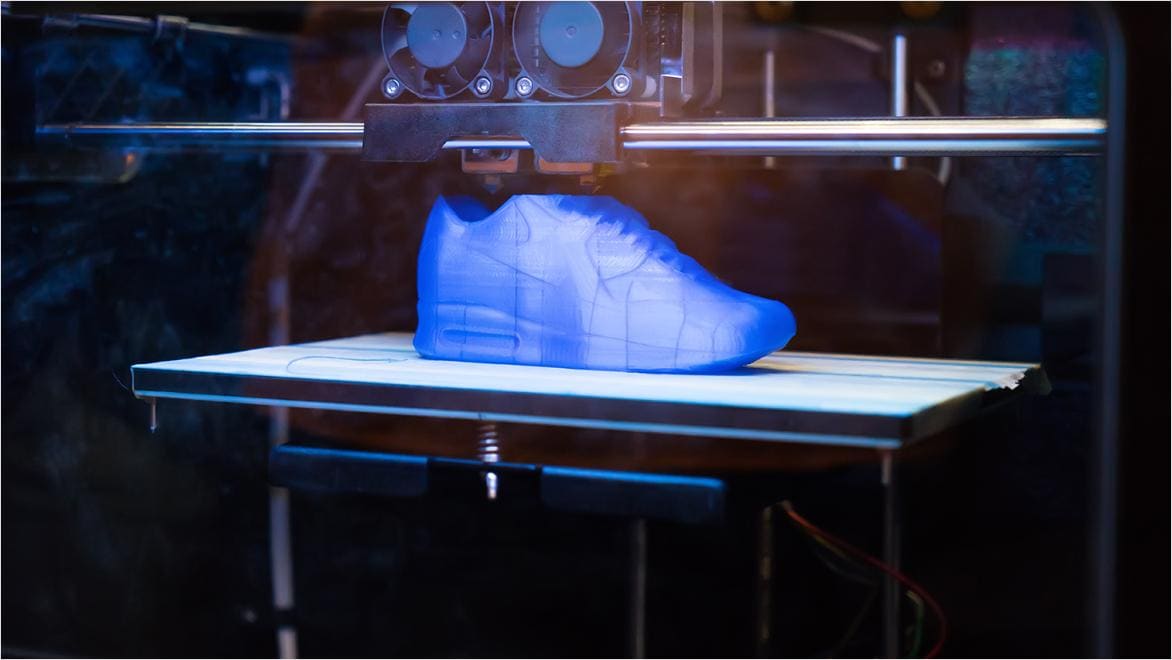

The manufacturing phase transforms the finalised design into a physical product. This involves pattern making, assembly and finishing, often requiring a variety of techniques like sewing, glueing or even 3D printing.

Both stages demand precision and expertise for the production of high-quality shoes.

Shoe design software is a specialised CAD tool used in designing, modifying and optimising shoe designs. It streamlines the design process with 3D modelling, rendering, simulation and collaboration features, enhancing accuracy and creativity.

Autodesk Fusion, a popular choice, supports sustainability by optimising material usage and facilitating additive manufacturing to reduce waste. It offers manufacturing-aware capabilities, feature-based automation and allows customisation of geometric patterns and volumetric lattices, enabling innovative and efficient shoe designs.

Visualise a product in 3D while still in the early phases of production allowing for a heightened level of accuracy compared to a sketch.

With 3D shoe design software, designers can create highly realistic and detailed virtual shoe models.

Speed up production timelines with the ability to quickly and accurately design, modify and visualise shoe designs.

Cloud-based product design software for manufacturing, 3D modelling, electronics, simulation and data management

The 3D shoe design process is a critical stage in the creation of footwear, where conceptual ideas are turned into tangible designs. Initial sketches provide a visual representation of the concept, which are then elaborated into detailed drawings. These drawings serve as the blueprint for the shoe, encompassing aspects such as aesthetics, comfort, functionality and alignment with market trends.

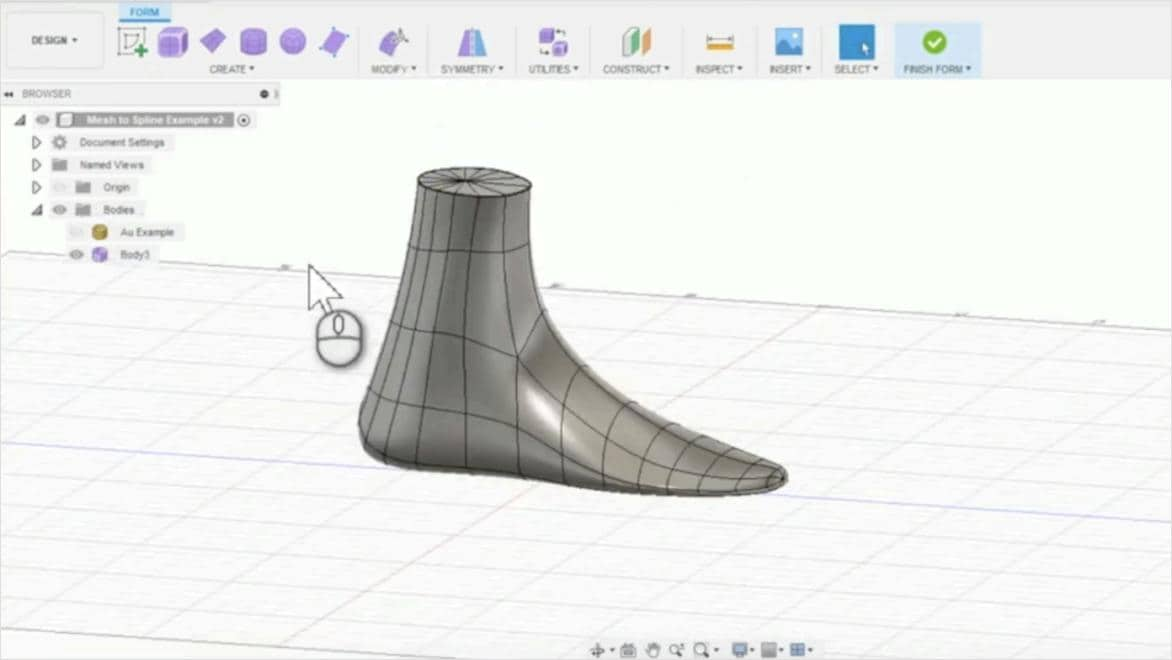

To transform these blueprints into a 3D reality, designers utilise advanced software like Autodesk Fusion. This tool allows for intricate 3D modelling and prototyping, offering a virtual simulation of the final product. This digital approach facilitates rapid modifications, promoting efficiency in the design process.

Following the design phase, the finalised shoe design undergoes the manufacturing process.

This is an innovative feature that uses AI to explore all the possible permutations of a solution, quickly generating design alternatives. It's perfect for optimising shoe designs for both aesthetics and functionality.

This tool is crucial in modern shoe design, as it allows for 3D scans of existing shoes or foot shapes to be converted into solid or surface models. This makes it easier to modify and refine designs.

Rendering is an essential tool in shoe design that allows designers to create realistic visuals of their designs. It provides a clear and accurate representation of what the final product will look like, including material textures and colours.

Additive manufacturing, also known as 3D printing, is a game changer in shoe design. It allows for the rapid creation of physical shoe prototypes, which accelerates the design process and reduces the time from concept to market.

Fusion's collaboration tools make it easier for design teams to work together. They allow multiple users to work on the same shoe design simultaneously, streamlining the design process and enabling more efficient teamwork.

This tool allows designers to create lightweight but durable structures within the shoe. By optimising the use of materials, you can design shoes that are both comfortable and sustainable.

The sculpt environment in Fusion gives designers the freedom to create complex, organic shapes with ease. This is especially useful in shoe design, where the aesthetics of the shoe can be as important as its function.

Symmetry tools make sure that shoe designs are consistent and balanced, enhancing their visual appeal. They also speed up the design process by allowing designers to change one side of the shoe and automatically applying them to the other.

These tools allow shoe designers to test and validate their designs under various conditions. They can simulate wear and tear, pressure distribution, and other factors to ensure the final product is both comfortable and durable.

The Autodesk Fusion Design Extension is a suite of advanced 3D design and modelling tools that can significantly enhance the process of footwear design. Here's how:

The Fusion Manufacturing Extension is a comprehensive suite of tools that significantly optimises the shoe manufacturing process in various ways:

Discover how leveraging Fusion and its innovative add-ons can significantly boost the effectiveness and impact of your sustainability initiatives in footwear design.

The Manufacturing Extension in Fusion provides advanced manufacturing tools that help produce complex, high-quality parts more efficiently. It optimises machining strategies to reduce waste, energy usage and production time, thus contributing to sustainability in shoe design.

Fusion's sustainability insights feature provides granular data on the environmental impact of different manufacturing processes. It helps designers make informed decisions about materials and methods to reduce the carbon footprint of their shoe designs.

Makersite for Fusion is a powerful add-on that provides comprehensive data on materials, costs and sustainability. It supports informed decision-making in shoe design, suggesting greener, less carbon-intensive materials and processes.

Pensole Footwear Design Academy is turning out a new class of shoe designers by incorporating hands-on prototyping, 3D modelling, and real-world workflows into its curriculum.

Under Armour used generative design and 3D printing, aided by Autodesk's software, to create the UA Architech. This lightweight, high-performance shoe illustrates future athletic gear manufacturing possibilities.

In this workshop, you'll use Fusion and ReCap Pro to create a shoe from a 3D scan. You'll learn to insert STL or Mesh, guide sketch insertion, create and modify T-spline bodies and use surface modelling for design features. The session covers all steps, from 2D sketch to 3D print-ready design.

The footwear industry is undergoing a significant transformation, with sustainability at the forefront of its evolution. Autodesk Fusion is playing a crucial role in this revolution by providing integrated solutions that embed sustainability into every step of the design and manufacturing process.

Learn more about footwear design software with these top questions frequently asked by users.

The shoe design process typically involves several steps: research on current trends and customer needs, conceptualising and sketching design ideas, creating 3D models of the designs, prototyping, testing for comfort and durability, and finally, production. Designers often use software like Autodesk Fusion to help with the 3D modelling, prototyping and testing stages.

New shoe designs are usually tested through a combination of prototype manufacturing, wear testing and computer simulations. Prototypes are made and worn to check for comfort, fit and aesthetic appeal.

In addition to these traditional methods, Autodesk Fusion's Computer-Aided Engineering (CAE) (US site) capabilities bring an added dimension to the testing process. The CAE tools allow for robust simulation and analysis of shoe designs under various conditions. For instance, stress analysis can be performed to evaluate the durability of the shoe. Thermal analysis can predict how the shoe material will react to different temperatures.

Furthermore, computer simulations in Fusion can be used to analyse factors like wear and tear, pressure distribution and comfort. This provides valuable insights that can be used to improve the design before it goes into production.

By leveraging Fusion's CAE capabilities (US site), shoe designers can conduct more comprehensive testing and validation, ensuring the final product's quality, performance and comfort.

Modern technologies like 3D printing (US site) have a significant impact on the shoe manufacturing process. They allow for rapid prototyping, which speeds up the design process and reduces the time from concept to market. They also enable more customisation, as individual components or even entire shoes can be printed to fit a specific individual's foot perfectly.

Autodesk provides a range of software that is widely used by shoe designers.

Fusion: Autodesk Fusion is a powerful, all-in-one software that allows you to design, model and manufacture products. The program is famous for its user-friendly interface and broad capabilities. Fusion is particularly popular in the shoe design industry because it can easily handle complex shapes and curves, which are often found in shoe designs. Fusion also allows for 3D printing, which is beneficial when prototyping designs.

AutoCAD: AutoCAD is another Autodesk software that can be used in shoe design. While it's primarily used for 2D drawings, it can also create 3D models. It's a versatile tool that's been in use in various industries, including footwear, for many years.

Alias: Alias is a more specialised software from Autodesk, often used in industries that require high levels of surface sophistication, like automotive and footwear. It offers tools for sketching, modelling and visualisation that are beneficial for shoe designers.

3ds Max: This software is mainly used in the animation and video game industry, but its powerful 3D modelling capabilities can also be used in shoe design, especially for creating photorealistic images of shoe models.

These Autodesk tools can be used individually or in combination to create a comprehensive workflow for shoe design and manufacturing.

Yes, Autodesk Fusion is available for free personal use for individuals who are doing home-based, non-commercial design projects. This version includes basic functionality. However, it is important to note that to qualify for free usage, users should generate less than $1,000 USD in annual revenue from their designs. You can register for a personal licence on the Autodesk website.

With tools like “Scan to Mesh to Solid Body or Surface Model” and the Sculpt Environment, Fusion allows designers to easily modify designs for a customised fit and look. For example, they can use a 3D scan of a specific individual's foot to create a shoe that fits perfectly. They can also use the sculpt environment (US site) to shape the shoe to match a specific aesthetic vision.

The realistic visuals created by Fusion's rendering tools can be a powerful aid in marketing and selling a shoe design. They provide a clear and accurate representation of what the final product will look like, which can help customers visualise the shoes and make a buying decision. These visuals can be used in marketing materials, sales presentations and online product listings.

Fusion offers a comprehensive set of tools for efficient design (US site), rapid prototyping (US site) and effective collaboration (US site), all-in-one platform. This can help shoe designers and manufacturers innovate faster, reduce time to market, and adapt quickly to changing trends and customer demands. By improving efficiency and enabling more innovative designs, Fusion can help shoe companies stay competitive in a fast-paced industry.

Autodesk Fusion supports sustainable design through features like generative design and volumetric latticing, which optimise material usage, and additive manufacturing, which reduces waste in prototyping. By using these tools, shoe designers can create designs that are not only attractive and comfortable, but also environmentally friendly.