Share this story

Stamhuis designs entire stores in minutes with generative design

Accelerating design when time is money

Since its founding in 1926, Stamhuis has built a reputation for quality and dependability. Based in the Netherlands, the firm specializes in retail shop construction and renovations and works closely with their clients to create custom solutions that are tailor-made to help them get the most out of their retail spaces. Stamhuis has been exploring the possibilities offered by construction software in boosting their efficiency and creating added value.

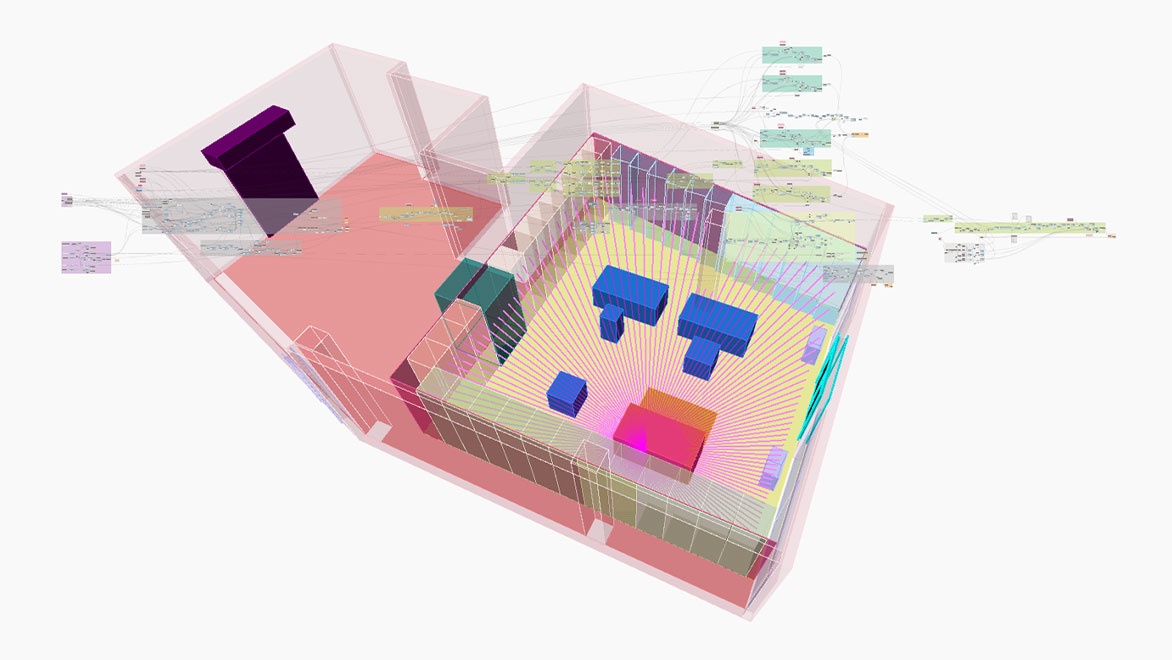

Script in Dynamo with the building contour and store design visually in the background. The automated design is based on the standard set variable..

Stamhuis will do 60 or more projects in a year for one customer alone

With clients ranging from supermarkets to liquor and convenience stores, Stamhuis will do 60 or more projects in a year for one customer alone. The volume of work is further complicated by timing, especially for redesigns where the entire construction from start to finish must be completed in one week. Such is the reality of retail.

BIM and prefabrication, the backbone of the company's success

“We know that if a store is closed and a customer goes to a different store, then they are likely to remain a customer there by the third visit,” says Ron Rijkers, Team Manager for BIM and Innovation, Stamhuis. “That’s why we really need to open a store within a week in order for our client to retain their own customers.”

The time crunch of design, construction, and installation is one thing. But, in the highly competitive and low-margin world of retail, cost-savings is critical across the board. That’s why Stamhuis has embraced as much automation, software, and emerging technologies in its work as possible to boost efficiency and create added value.

BIM, collaboration, and prefabrication have been a backbone of the company’s success. The firm has also optimized the customer’s decision-making process by providing VR and AR experiences for the store designs. In the past year, they’ve now taken another leap with generative design.

“We realized that if we don’t start with generative design now, we would be way behind in a few years. We think generative design is the future.”

—Ron Rijkers, Team Manager for BIM and Innovation, Stamhuis

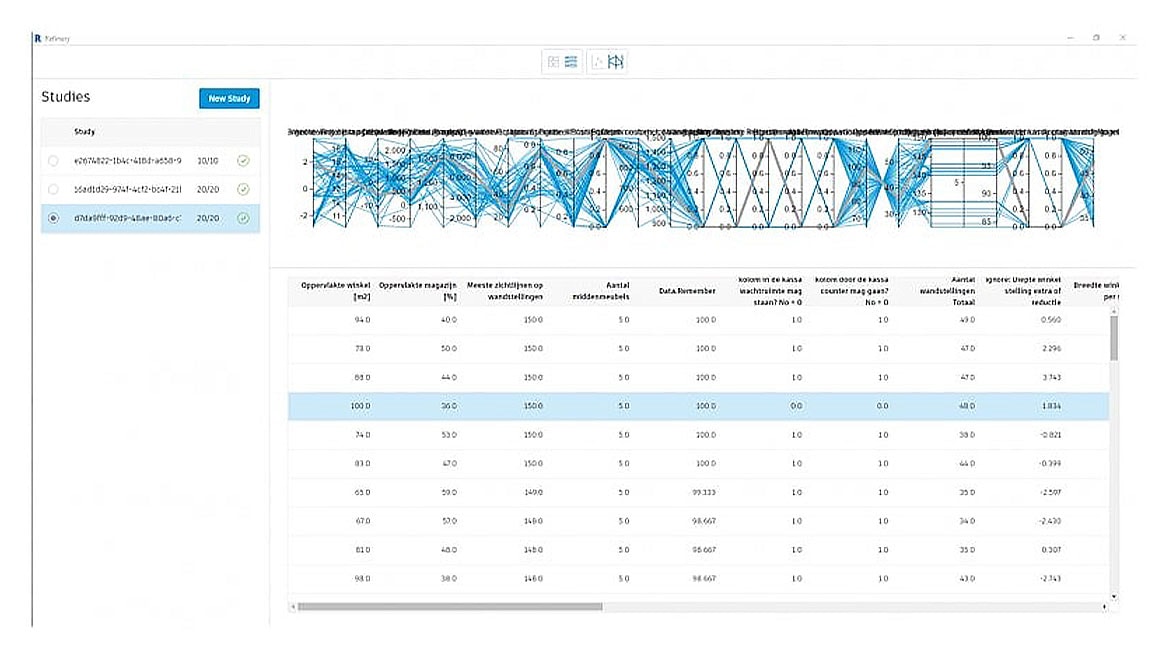

Design studies in Project Refinery. After setting the most important KPIs, the generative design generated results are filtered and sorted in the correct way.

Pilot proves the potential of generative design

For the first foray into generative design, Stamhuis took a recent design of a liquor store and put generative design to the test.

The company wanted to optimize and see the outcomes for different key aspects of a successful retail design, including the location and size of the cash register area, ratio between the shop and inventory storage, shelf spacing, aisle size, seller’s field of vision, and more. It was also a chance to experiment with a way to help free a designer’s time for more strategic work.

Generative design solutions help optimize design options

After getting together their initial plans, the team spent three days in a conference room to set up a computational model with Dynamo, which helps to automate tasks and create visual logic for exploration of parametric designs. Autodesk’s generative design beta Project Refinery then helped to automate and optimize the design options. Since many of Stamhuis’ projects are large-scale and standardized without much variation, they were able to easily capture much of a designer’s actions. In the end, they created a script and settled on 40 ideal options for the liquor store. This set of informed options could provide the measurable performance outcome for better decision-making and communication with clients.

“We really didn't expect that all the decisions made in a design process could be caught in a script,” Rijkers says. “You actually get better results because it’s an educated design, and you can determine the outcome with fixed key performance indicators and consistency.”

The quality of the design was one thing—but the time savings was quite another.

“It would take one of our designers four hours for a typical design of these liquor stores and the standard layout. Now, in the span of 15 minutes we can gather the information, run the script, and receive 40 optimized design options.”

—Ron Rijkers, Team Manager for BIM and Innovation, Stamhuis

How to get going with generative design

However, now that they can generate these different designs, the team must also figure out the best way to present multiple designs to a customer. They’re currently programming a tool that can translate the three best designs into a model to show clients in a VR environment.

Moving forward, Stamhuis also sees customers being able to convey their key priorities—whether it’s the layout, less use of materials, and much more—and have a choice of optimized designs with a much faster process. But there is a learning curve all around.

“Generative design is so new, and it can be hard for customers to grasp it,” Rijkers explains. “So we’re really trying to take them step-by-step into this new world.”

Rijkers also has a bit of advice for anyone looking to start experimenting and working with generative design.

“Just try it,” he says. “If you don’t, you won’t know the great information that you might be missing. But it’s not something you can just do in addition to your regular, daily work. You really need to focus on it and understand it.

“You will also need positive change management in order for the company as a whole as well as individuals to understand the new approaches and the benefits,” he continues. “But it’s all well worth it when you start seeing the results with generative design.”

“For the designer, he can focus more on construction or strategy and relationships with the customers instead of making the same shelves over and over again. The designers are beginning to realize what an advantage it will be to their work.”

—Ron Rijkers, Team Manager for BIM and Innovation, Stamhuis