& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

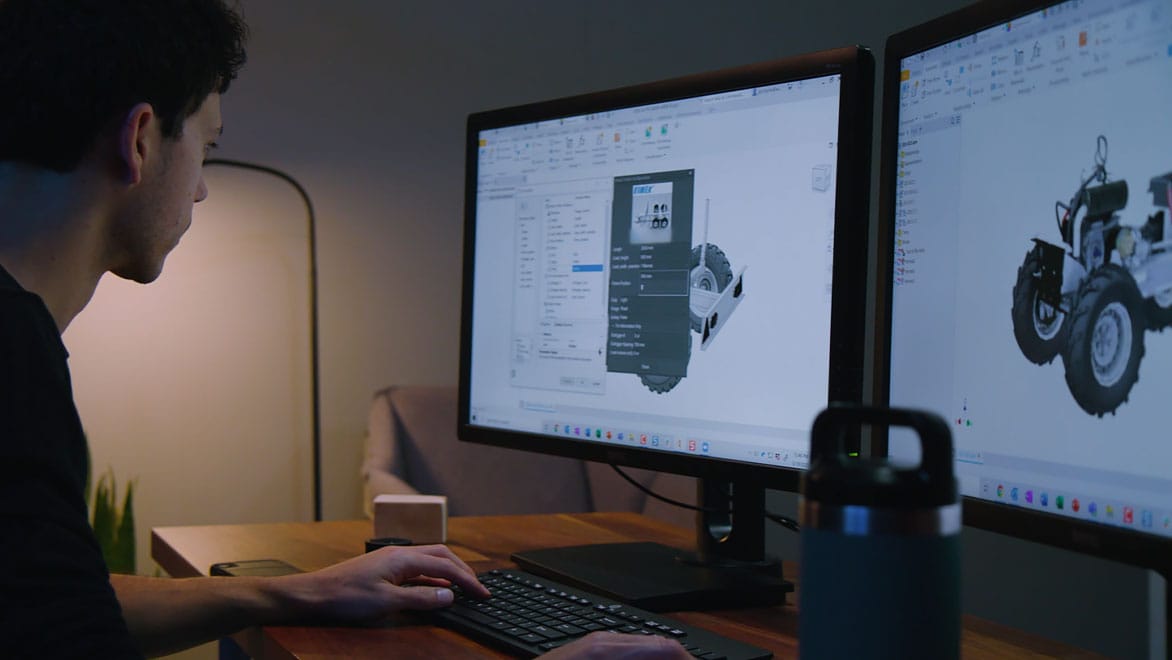

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

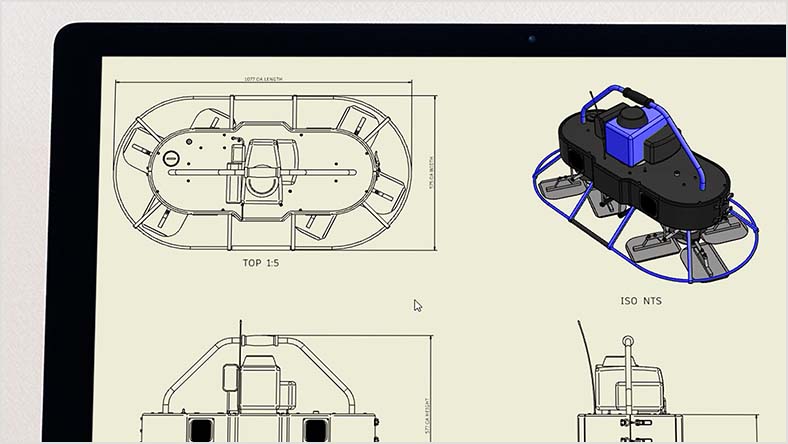

Design automation lets you capture and reuse engineering knowledge and intent. Automation not only helps reduce errors and time spent on tedious, repetitive modeling tasks, but it can also be scaled to streamline downstream development processes.

Design automation can mature from automating basic parameters to full-scale product configuration. Setup can be as simple or complex as your current needs demand. Learn how iLogic Technology, found in Autodesk Inventor, lets engineers easily use rule-based design without complex coding.

Sheet metal parts and welded frames often include standard features that require simple, yet tedious modeling. Eliminate busywork by automating the creation of typical product features.

Manually modifying models to meet customer specs can drain engineering resources. Define parameters to create your 3D model, and easily set rules that drive a custom product configurator.

Extend automation beyond engineering with simple-to-code tools. Easily capture and execute standard processes for the creation of drawings, toolpaths, and other documentation.

Powerful product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

Get Inventor + AutoCAD + Autodesk Fusion + more—Professional-grade tools for product development and manufacturing planning.

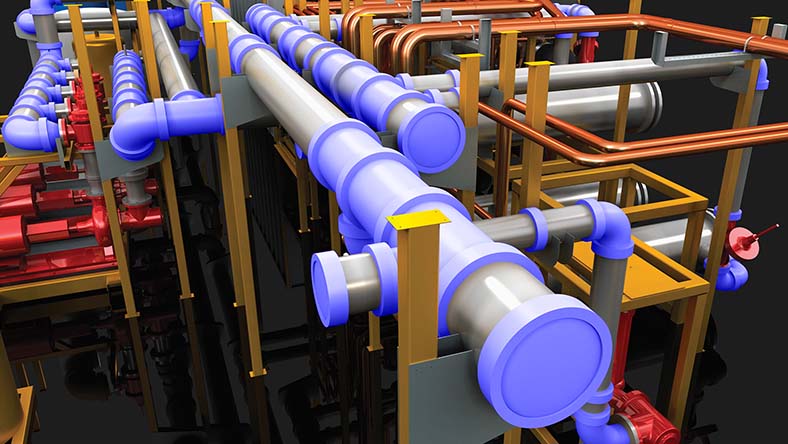

Image courtesy of FS-Elliott

See how air compressor manufacturer FS-Elliott uses iLogic in Inventor to model custom impellers.

“The parts that we make have to be very precise, and to model that manually takes a lot of time. There had to be a better way to do this.”

—Alex Curtin, Product Manager, FS-Elliott

Hear firsthand how engineering teams at FS-Elliott and Viewrail have used automation to increase the agility of their workflows and achieve impressive results.

Read the Lifecycle Insights report to learn how manufacturers are finding meaningful ways to automate core product development processes in order to gain—and keep—competitive advantage.