& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Embodied carbon refers to the total greenhouse gas emissions generated throughout the lifecycle of materials, from extraction and manufacturing to transportation, construction, maintenance, and disposal. Unlike operational carbon, which comes from a building’s energy use over time, embodied carbon is locked into its materials from the start.

For architects, engineers, and construction professionals, embodied carbon analysis helps guide material selection, structural efficiency, and reuse strategies to reduce a project’s carbon footprint. Beyond the built environment, embodied carbon analysis is also an essential parameter in environmental science, where it informs climate impact assessments, and in water treatment, where material choices affect infrastructure sustainability. Public health experts consider embodied carbon in the context of air quality, resource depletion, and the broader environmental factors that influence community well-being. Integrating embodied carbon considerations is essential for driving sustainable innovation as industries work toward carbon reduction goals.

Find out how Autodesk Forma can help AEC professionals analyze environmental impact.

Embodied carbon refers to the greenhouse gas emissions at every stage of a building or piece of infrastructure’s lifecycle, namely:

By using embodied carbon analysis to build a picture of carbon use through all of these stages, changes and improvements can be made to reduce carbon overall.

Decarbonizing construction starts with intentional choices that reduce a building’s carbon embodied footprint before it is built. Low-carbon materials—such as mass timber, recycled steel, and low-carbon concrete—can drastically cut emissions, while optimizing designs for material efficiency minimizes waste. Adaptive reuse and modular construction further reduce demand for carbon-intensive materials, keeping valuable resources in circulation and extending their lifespan. By embracing circular economy principles, such as deconstruction planning and material repurposing, the industry can shift from a waste-heavy model to one that prioritizes sustainability and resilience.

True impact comes from collaboration. Architects, engineers, and builders must work together to assess and lower embodied carbon using life cycle assessments (LCAs) and environmental product declarations (EPDs). Partnering with suppliers who prioritize transparency and innovation in manufacturing can push the industry toward lower-carbon solutions. By embedding decarbonization strategies early in the design and procurement process, professionals can create more sustainable buildings and a more climate-resilient future.

While there are compelling environmental reasons for reducing embodied carbon in building and infrastructure designs, there are also a number of business benefits to doing so.

Reducing the amount of embodied carbon in your designs can often mean using less material, and this can result in a significant cost reduction, particularly if you’re using the same design in multiple instances.

As the industry moves towards a focus on sustainability, AEC businesses that make sustainable practices like embodied carbon analysis a key part of their business can position themselves as industry leaders.

Adopting an approach that considers embodied carbon in buildings from the design process onwards will help you move away from practices that may fall into obsolescence in the future.

Many people today are concerned about the environment and want to see more sustainable practices adopted. Taking a whole life carbon approach to projects can boost the motivation and involvement of workers at every stage of the project.

Understanding how to calculate embodied carbon is essential for reducing the environmental impact of buildings. Embodied carbon assessment determines emissions across a material’s lifecycle, from raw material extraction and manufacturing to transportation, construction, maintenance, and disposal. A life cycle assessment (LCA) is the standard method used, relying on data from environmental product declarations (EPDs) and industry databases to quantify emissions. Tools like an embodied carbon calculator or a concrete embodied carbon calculator help designers, engineers, and contractors compare materials and make informed choices that lower a building’s overall embodied carbon footprint.

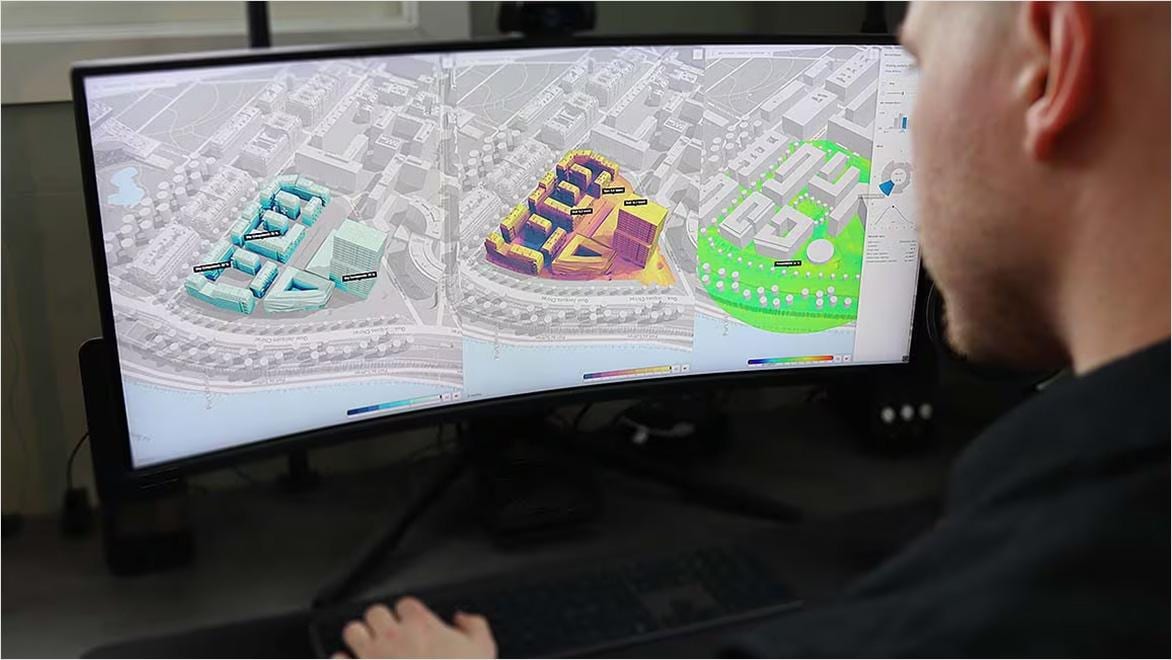

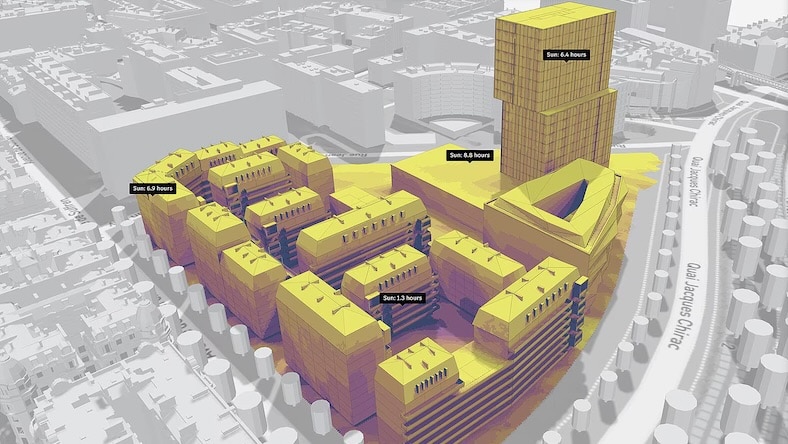

For those wondering how to calculate embodied carbon in a building, several key factors come into play. Material selection, transportation distances, construction methods, and a material’s expected lifespan all influence total embodied carbon. Many professionals use embodied carbon calculations to analyze emissions at different project stages, ensuring carbon reduction strategies are integrated early in the design process when changes carry the lowest cost risk. For example, Autodesk Forma’s Embodied Carbon Analysis tool enables designers to gain a more thorough understanding of carbon impacts from building form, structure, and primary material choices during site feasibility and massing studies that happen at the start of the project planning process. Leveraging these embodied carbon reporting tools during early concept planning gives teams the greatest opportunity to impact decisions that contribute to a low-carbon built environment.

Perkins & Will

A global design firm designs California’s first multistory mass timber building with Revit and the Embodied Carbon in Construction Calculator.

Image courtesy of David Wakely

Stantec

A global leader in sustainable architecture partners with Autodesk Forma to pioneer tools that boost carbon-conscious decisions from concept to construction.

Lake|Flato

A sustainable architecture firm uses Revit to turn a 100-year-old building into a future-focused hybrid workplace.

Image courtesy Robert G. Gomez

Cloud software that offers powerful, easy-to-use, AI-powered tools for pre-design and schematic design. Making the right decisions in the planning phase has never been easier.

Plan, design, construct, and manage buildings with powerful tools for Building Information Modeling.

Get up to speed with using Autodesk software for embodied carbon analysis.

Discover the basics of using Autodesk’s Insight for Revit to create an energy analytical model and then analyze it. Across multiple tutorials, topics include:

Learn how to use Forma for data-driven analyses, how to enhance cross-product design workflows, and how to collaborate effectively. Topics include:

See how one of the most significant contributors to global carbon emissions also holds the greatest opportunity to reduce carbon impacts.

Learn how total carbon analysis for architects offers insights into carbon outputs of design decisions from the earliest stages of a project.

Explore a new generation of carbon emissions calculators helping architects and contractors measure and manage embodied carbon across the lifecycle.

Visualize opportunities for carbon reduction and track impacts as building designs develop with Autodesk Insight software.

Weigh the trade-offs between materials from the beginning of the design process and make informed decisions during the planning stages with Autodesk Forma’s Embodied Carbon Analysis.

See how the Revit Energy Analytical Model is used for total carbon analysis and learn step-by-step workflows to maximize the tool from concept to design.

Among common building materials, aluminum has the highest embodied energy, ranging from 200–250 MJ/kg, due to its energy-intensive extraction and refining process. Other high-energy materials include plastic (80–120 MJ/kg), copper (40–50 MJ/kg), and steel (20–35 MJ/kg), while materials like concrete (1–2 MJ/kg) and timber (8–12 MJ/kg) have significantly lower embodied energy. However, recycling drastically reduces these impacts—recycled aluminum uses only 5–10% of the energy required for virgin production, and recycled steel is far less carbon-intensive than its virgin counterpart. This underscores the importance of material reuse, recycling, and low-carbon alternatives in reducing embodied carbon in construction.

Calculating the embodied energy of building materials involves measuring the total energy required across their lifecycle, from extraction and processing to transportation, construction, use, and disposal. This is typically done using environmental product declarations (EPDs), life cycle assessments (LCAs), and industry databases that provide embodied carbon energy values in megajoules per kilogram (MJ/kg). The total embodied energy is determined by multiplying a material’s energy factor by the quantity used, while also accounting for transportation distances and construction methods. Tools such as embodied energy databases, LCA software (such as One Click LCA, Tally), and embodied carbon calculators help professionals make data-driven decisions to reduce energy-intensive materials and prioritize sustainable alternatives.

The embodied energy of particleboard typically ranges from 8–12 MJ/kg, influenced by factors such as material sourcing, adhesive content, and manufacturing processes. Made from wood chips and sawdust bonded with resins, particleboard has a moderate amount of embodied carbon – higher than solid timber but lower than synthetic materials like plastics. The use of recycled wood fibers helps reduce its environmental impact, though factors like resin type, pressing techniques, and transportation distances can affect its total energy footprint. When sourced responsibly and manufactured with lower-carbon processes, particleboard can be a more sustainable alternative to virgin wood-based panels.

The embodied energy and carbon of structural materials vary widely, with aluminum (200–250 MJ/kg, 10–12 kg CO₂e/kg) and virgin steel (20–35 MJ/kg, 1.5–2.5 kg CO₂e/kg) having the highest impacts due to energy-intensive production. Concrete (1–2 MJ/kg, 0.1–0.2 kg CO₂e/kg) has low embodied energy per kilogram but is used in large volumes, making its total carbon footprint significant. Timber and cross-laminated timber (CLT) (8–12 MJ/kg, -0.5–0.2 kg CO₂e/kg) can be carbon-negative when sourced sustainably, as they store carbon rather than emit it. Recycled materials, low-carbon concrete, and efficient material selection help reduce emissions, making life cycle assessments (LCAs) and embodied carbon analysis essential tools for sustainable construction.

Autodesk offers a range of tools for carbon footprint analysis. Forma has a suite of powerful AI-driven tools that can help in early-stage massing and material choices, while Insight and Revit’s energy analytical model can aid you in carrying out embodied total carbon assessments.