Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

THE FUTURE OF MAKING

DIGITAL TRANSFORMATION FOR MANUFACTURING

Manufacturers now face some of the biggest challenges in decades, from rising competition and increasing production costs to disrupted workforces and supply chains. Digital transformation offers a new way forward, connecting people, processes, and the entire manufacturing ecosystem more effectively to help you design and make products faster with lower costs and less waste.

Image courtesy of Lorem ipsum

What is digital transformation for product development?

Digital transformation is a way for design and manufacturing companies to offer significantly greater value to their customers, employees, and stakeholders by breaking down silos between departments and helping entire organizations work smarter together. It's about using a connected data platform to make better-informed decisions, drive more innovation, increase productivity, and create new business opportunities.

Connected data and cloud platform

Keeping critical product development processes moving forward requires connected teams and data across the entire organization. Enable your teams to make better-informed decisions quickly with access to the right data at the right time.

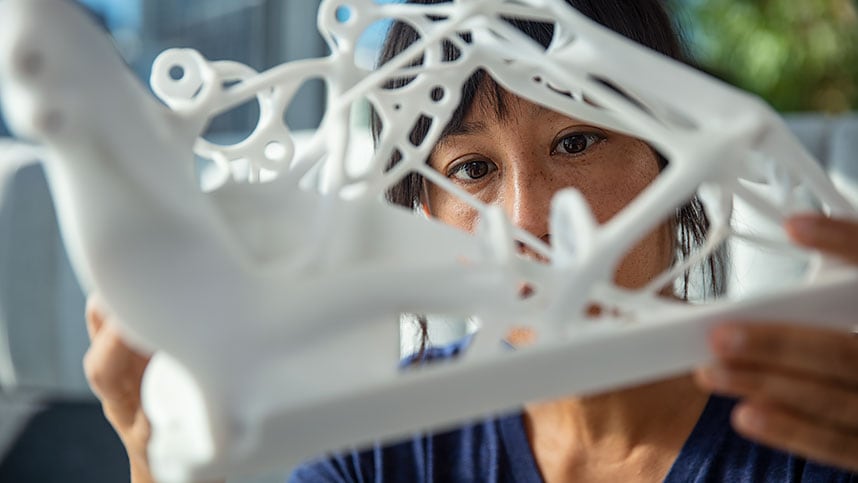

Design and manufacturing convergence

To compete in the future, you’ll need to connect your design and manufacturing processes so that all team members can collaborate seamlessly. Bringing the studio and shop floor closer together can make your products compete more effectively in the market that drives more profits for you.

Manufacturing confidence with digital transformation

-

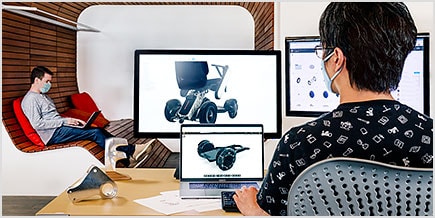

Convergence

Digital transformation begins with convergence, connecting your organization using data while bridging the gap to bring together different disciplines such as CAD, CAM, or CAE and different teams in one product development and manufacturing environment.

-

Collaboration

Data is the key to connecting your entire manufacturing ecosystem and keeping your business operational. Accessing data via the cloud has become a necessity for collaboration; it’s a critical component that connects end to end, from initial concept to delivery to your customers.

-

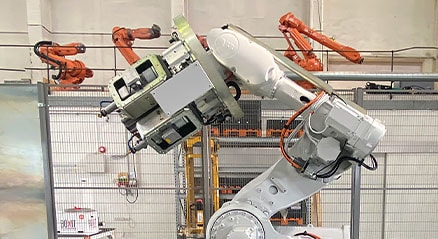

Automation

Automation eliminates the delays of manual working. With automation tools, such as generative design and robotics, you can streamline multiple processes and accelerate your product development across all departments that increase innovation and creativity.

Digital transformation podcast

The Art of the Impossible is a digital transformation podcast for design and manufacturing professionals. The series explores how to leverage technology, processes, and people to make seemingly impossible goals achievable. If you run a design and manufacturing business and want to transcend traditional boundaries, this podcast is for you.

What are the benefits of digital transformation?

Faster decision making

Make better-informed decisions, drive more innovation, and realize new possibilities. Connected data offers actionable insights so people across the entire organization can make better decisions faster.

Increased productivity

Digital transformation better connects people, processes, and manufacturing ecosystems to help you achieve more machine uptime and boost output and productivity while reducing waste and re-work.

Product validation

Quickly use data to check each stage of your product's lifecycle to ensure a quality-controlled process has been approved before moving on to manufacturing, production, distribution, sales, and end use.

Improved innovation

Innovate your business by automating your product development processes with tools like generative design that take advantage of artificial intelligence and machine learning.

Customer stories

VISICONSULT X-RAY SYSTEMS & SOLUTIONS

A family-owned industrial X-ray machine business based near the Northern German town of Lübeck is undergoing a generational handover and investing heavily in the digitalization of processes, artificial intelligence (AI), 3D printing, and sustainable growth.

ODICO ROBOTICS

In 2019, Denmark set a new record by sourcing a massive 47% of its electricity consumption from wind power alone. Today, manufacturing robots from Danish company Odico are set to revolutionize this industry even further.

TECHN GMBH

TechN GmbH develops innovative water-cooling systems for high-end consumer graphic cards. Fusion Lifecycle manages its engineering data, engineering processes, and collaboration with suppliers in a single environment.

The latest on digital transformation

-

Top 5 manufacturing trends

Check out the latest trends you should watch, including smart products, data automation, and the convergence of manufacturing, construction, and design.

-

The future of making is digital

Businesses should adopt smart manufacturing to help streamline processes, increase productivity, stay competitive, and prepare for the future.

-

Future proof supply chains

Supply-chain vulnerabilities are now impossible to ignore. Across the board, firms are looking to make manufacturing and supply networks more resilient.

Privacy settings | Privacy/Cookies | About our Ads | Legal | Report Noncompliance | Do not sell my personal information | Site map | © 2020 Autodesk Inc. All rights reserved