& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Smart manufacturing refers to the use of interconnected digital technologies, both physical and virtual, to digitise and optimise production processes. A variety of Industry 4.0 technologies are used for this, resulting in what has been dubbed the ‘smart factory’. Smart manufacturing relies on the collection of data, the implementation of automation, and the connection of all these technologies to form a symbiotic whole that results in greater efficiencies. Smart manufacturing is on the rise in India and globally, and Autodesk offers a number of solutions to help you keep up with the trend.

Various types of technologies are used in the smart factory, including:

The Industrial Internet of Things (US Site) is a network of connected devices within the smart factory environment. Each of these is connected to the other, sharing data and automating processes.

By using the vast amounts of data collected from IIoT devices and other sources in real-time, insights can be found, efficiencies identified and production bottlenecks in the smart factory solved.

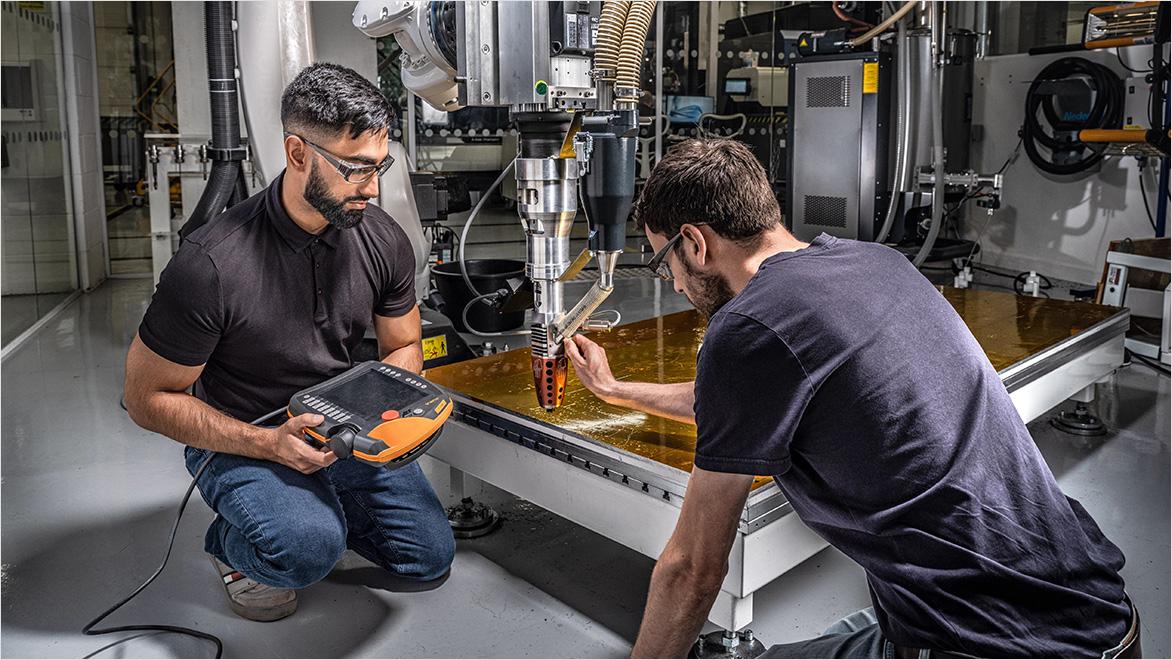

Image courtesy of Pixabay

Big data is made understandable via the use of artificial intelligence algorithms. These allow the detection of patterns and the optimisation of industrial processes.

Cloud computing allows you to harness software on remote servers via the internet, providing greater flexibility and lower overheads. Autodesk software like Fusion offers cloud-based Industry 4.0-ready solutions for smart manufacturing environments.

Former chairman and CEO of General Electric, Jack Welch, famously said, “If the rate of change on the outside exceeds the rate of change on the inside, the end is near.” For any business holding on to old ways of doing things, it’s time to take note.

As the world pushes forward with Industry 4.0 (US Site), India’s manufacturing sector is undergoing a profound transformation. Smart manufacturing is leading this shift, and digital technologies and automation are reshaping the way we design, produce, and deliver products.

What was once a choice is now a necessity. To stay competitive, manufacturers must adapt or risk falling behind. Industry 4.0 and smart manufacturing are not just concepts —they offer a roadmap for building the businesses of tomorrow, driven by data, machine learning, and connectivity.

.

India’s path to smart manufacturing began in the early 2000s with a gradual shift toward automation and digitisation. Early adopters were primarily larger corporations in sectors like automotive and aerospace, but widespread adoption has gained momentum among small to mid-market manufacturers in recent years.

Key drivers behind this evolution include the need for greater efficiency, global competition, and responsiveness to market needs. Government initiatives such as “Make in India” and “Digital India” have further incentivised the adoption of smart manufacturing technologies, encouraging international collaboration and attracting foreign and domestic investment into the sector. The pandemic accelerated the shift, as it exposed vulnerabilities in traditional production systems—vulnerabilities that smart manufacturing is uniquely positioned to address.

For manufacturers in India, the transition to smart manufacturing and Industry 4.0 may seem challenging, but the rewards far outweigh the costs. Increased productivity, reduced operational expenses, improved product quality, and faster time to market are all achievable with the right investments in smart factory technology and workforce training.

The rise of smart manufacturing is about more than just automating manual processes. It's about creating a connected smart factory ecosystem where data, design, and production work together seamlessly. Indian companies that embrace Industry 4.0 will be well-positioned to gain a significant competitive advantage, both in the domestic market and globally.

As Industry 4.0 continues to evolve, Indian manufacturers must focus on investing in the right technologies, developing a skilled workforce, and fostering a culture of continuous improvement. The future of manufacturing in the region is undeniably bright, and smart manufacturing is key to unlocking its full potential.

2D and 3D CAD tools, with enhanced insights, AI-automations and collaboration features. Subscription includes AutoCAD on desktop, web, mobile and seven specialized toolsets.

Powerful product design and engineering tools for 3D mechanical design, simulation, visualisation and documentation.

There are many reasons why a growing number of businesses are turning to smart manufacturing. These include:

Smart factories are able to optimise the use of resources, machinery and personnel, and a significant consequence of this is that they require less money to run than those that rely on older production models.

The ability to monitor production processes and related data in real-time means that a smart factory is able to identify and prevent defects early.

Smart industry technologies allow inefficiencies to be eliminated and processes to be endlessly improved.

In the push towards greener production, smart factories can help you conserve resources and lower energy usage by leveraging data.

With a world-class workforce and a booming manufacturing industry, India has the potential to rise to a dominant global position in the production of various types of goods. By embracing smart manufacturing and Industry 4.0 technologies, Indian businesses have the potential to spearhead this change, by becoming more efficient, more competitive and offering highly desirable products that are boosted by smart manufacturing tech like machine learning, real-time data via Internet of Things (IoT) (US Site) devices and advanced robotics.

Recent system shocks, such as COVID-19, have proven to be a wake-up call for the manufacturing industry. The disruption of supply chains, labour shortages, and reduced demand highlighted the need for more resilient, data-driven production environments. Below, we share the two main bodies in India working to tackle these challenges.

Government initiatives are laying the groundwork to move India’s manufacturing sector from reliance on manual labour and traditional processes to smart manufacturing and industry 4.0. “Make in India” and “Digital India” have borne many sub-initiatives that tackle challenges faced by the sector from raising investments to upskilling the workforce. One such programme is the Production Linked Incentive Scheme (PLI) which works to boost the local manufacturing industry. It’s helping to position India as a global hub by encouraging and driving capabilities in the country for developing core design and manufacturing components.

In the private sector, many companies are investing in smart manufacturing and Industry 4.0 best practices to optimise operational efficiency and boost innovation. Smaller firms and startups entering into the space are rethinking manufacturing design and production processes from the ground up, harnessing the power of simulation (US Site), generative design (US Site), and predictive analytics to maximise efficiency from the design phase to production and post-manufacturing.

Autodesk has been instrumental in India’s transition to smart manufacturing. Its solutions empower designers and engineers to create more connected, data-driven manufacturing processes that streamline workflows and enhance productivity across industries likeautomotive, consumer goods, and architecture.

Autodesk Fusion brings the entire product development process—design, engineering, and manufacturing—into one powerful platform, offering an integrated workflow that supports manufacturers in their transition to Industry 4.0 and smart manufacturing. One of Fusion’s standout features is generative design, which uses machine learning to explore thousands of design possibilities and select the best ones based on factors like weight, cost, and material use.

Fusion also enables engineers to simulate (US Site), test, and validate designs virtually before creating physical prototypes. This reduces material waste, lowers risks, and speeds up time-to-market—critical advantages for Indian manufacturers competing globally.

For manufacturers in India, the transition to smart manufacturing and Industry 4.0 may seem challenging, but the rewards far outweigh the costs. Increased productivity, reduced operational expenses, improved product quality, and faster time to market are all achievable with the right investments in Industry 4.0 technologies and workforce training.

The rise of smart manufacturing is about more than just automating manual processes. It's about creating a connected ecosystem where data, design, and production work together seamlessly. Indian companies that embrace Industry 4.0 and the concept of the smart factory will be well-positioned to gain a significant competitive advantage, both in the domestic market and globally.

As Industry 4.0 continues to evolve, Indian manufacturers must focus on investing in the right technologies, developing a skilled workforce, and fostering a culture of continuous improvement. The future of manufacturing in the region is undeniably bright, and smart manufacturing is key to unlocking its full potential.

Explore podcasts, videos, and eBooks that demonstrate how digital transformation can boost manufacturing efficiency, reduce waste, and lower costs.

Discover the challenges facing smart factories of the future and learn what you need to get prepared and develop tailored solutions for your specific production needs.

See how a metalwork company enhanced its product data management by leveraging Autodesk’s digital solutions for smart manufacturing.

Smart manufacturing and Industry 4.0 are terms that are frequently used interchangeably, but the former can be seen to be a subset of the latter. Industry 4.0 refers to the Fourth Industrial Revolution and the integration of digital technologies into industry of all kinds. Smart manufacturing refers to the use of these Industry 4.0 technologies within the manufacturing sphere.

Industry 4.0 in India refers to the ongoing integration of a variety of digital technologies in industries across the country, including in the manufacturing sector. These Industry 4.0 technologies, which together form the concept of the smart factory, include machine learning/AI, data analytics, cloud computing, the Internet of Things and robotics.

Challenges in adoption of smart factory technologies and Industry 4.0 processes include perceived high initial investment costs, the skills gap in the workforce, resistance to change from traditional practices, and concerns about data security and infrastructure.

Key Industry 4.0 technologies include the Internet of Things (IoT) (US Site), artificial intelligence (AI) (US Site), big data analytics, robotics (US Site), 3D printing, cloud computing, and cyber-physical systems.

SMEs adopting smart manufacturing and Industry 4.0 technologies stand to gain improved efficiency, enhanced product quality, faster innovation and time to market, and access to global markets.